Bridging the Skilled Labor Gap in the Manufacturing Industry

The skilled labor gap is a real and pressing concern for manufacturers. As baby boomers retire or leave the workplace, there are simply not enough skilled workers to replace them. This is expected to have a major impact on the manufacturing industry as companies struggle to find the talent they need to keep production going.

In fact, according to a study by The Manufacturing Institute, more than two-thirds of manufacturers are concerned about the lack of skilled labor available to replace these retiring workers.

According to McKinsey, in the next ten to fifteen years, the pulp, paper and packaging industry will be under an immense amount of pressure to keep up with rapidly changing developments. New business models brought about by an increasingly online world, along with a heightened need for innovation and commercialization of products, will mean that the talent pool within these companies will be put under immense strain.

Furthermore, digitalization is set to have a profound effect on manufacturing processes – meaning that even the content of work will be transformed. Consequently, it is clear that forest-products companies must start to invest in their talent pool now, in order to avoid being left behind in the years to come.

The days of workers toiling away in dirty, dangerous factories are coming to an end. With the rise of automation and artificial intelligence, many jobs that have traditionally been performed by human beings are now being done by machines. This shift is already underway in the pulp, paper and packaging industry, where 60 percent of all tasks can now be automated. In the coming years, this trend is only going to accelerate, with more than 30 percent of physical and manual skills becoming obsolete.

This presents a major challenge for companies in the industry, who will need to reskill their workforce to keep up with the times. But it also presents an opportunity. Those companies that are able to embrace the future of work will find themselves with a major competitive advantage.

So the question is: which side are you on?

As baby boomers leave the manufacturing workforce, they take with them years of experience and knowledge.

The labor shortage in the manufacturing industry has been steadily worsening over the years as more experienced workers retire without passing on their skills to the next generation. The result is a widening skills gap that threatens to hamper the industry’s ability to compete in the global marketplace.

The knowledge these baby boomers are taking with them cannot be easily replaced, which means the lack of experienced workers that can operate and maintain sophisticated equipment is a real and present danger to the manufacturing industry.

That being the case, manufacturers are turning to artificial intelligence (AI) to help bridge the gap. By leveraging AI technologies, manufacturers can train machines to perform tasks that previously required human expertise.

AI can help to close the labor gap in three ways: by providing a digital workforce that can operate 24/7, by training the next generation of workers, and by improving productivity, thereby reducing the need to replace workers one-for-one.

AI in manufacturing can be used to help with things like quality control and product inspection. By using AI, manufacturers can reduce their reliance on human labor. This is especially helpful in industries where there is a lot of repetitive work that needs to be done.

- A digital workforce is not subject to human limitations, such as breaks or vacations. They can also be easily scaled up or down to meet changing labor needs. Additionally, because they are not human, they do not need to be paid and can work for free.

- The second way AI can help is by training the next generation of workers. By using historical data and collecting domain expertise from current workers, AI can create models that show the most efficient way to complete a task. These models can then be used to train and support new workers, significantly reducing the time it takes them to ramp up and be productive.

- Properly deployed, the combination of predictive analytics and AI can provide next-level insights that can reduce the need for human intervention and allow few employees to deliver the output/impact of many. For example, by predicting a problem before it occurs and taking action to correct it in real-time, manufacturers have been able to reduce staff, improve quality and increase production.

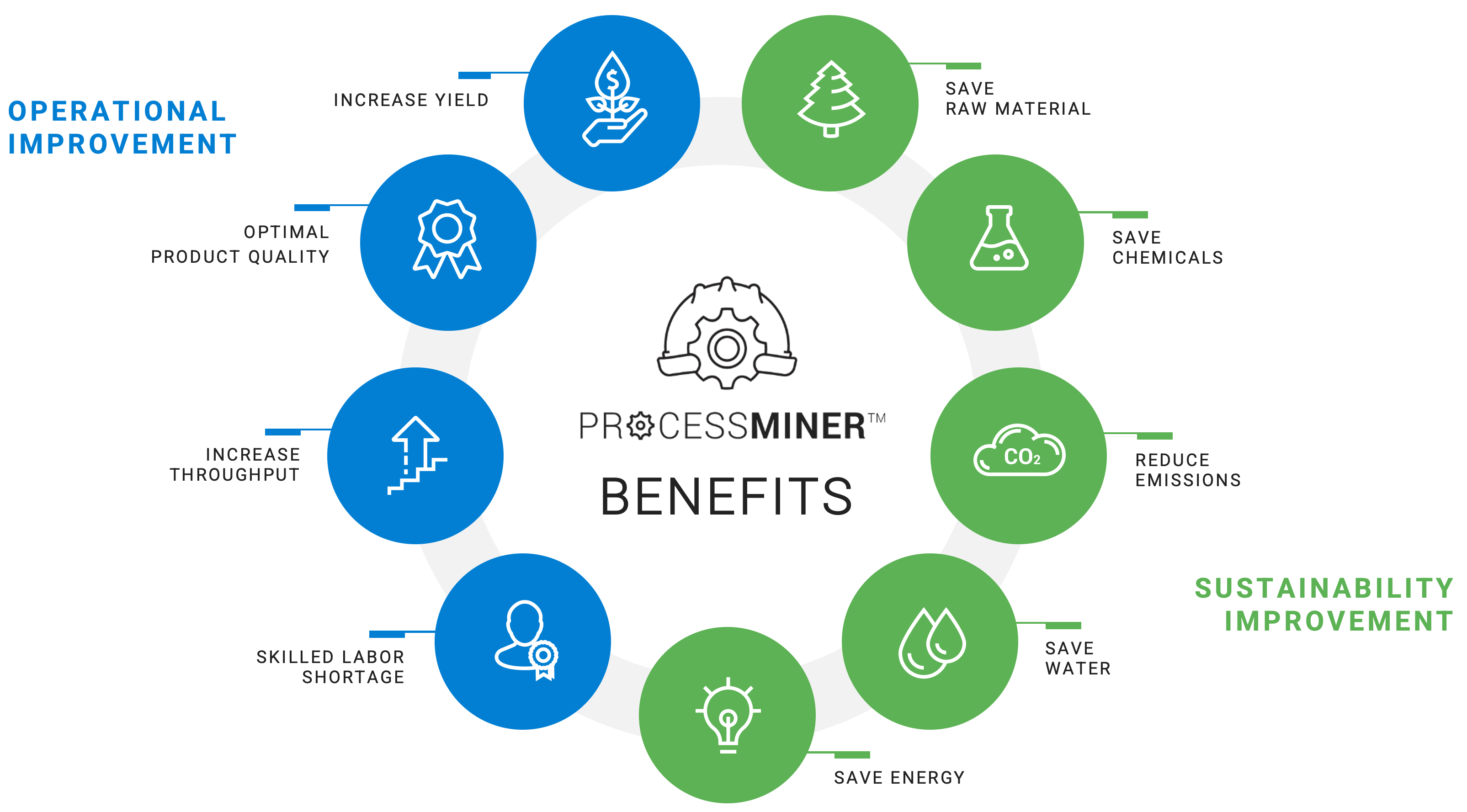

ProcessMiner, an industry-leading AI platform, helps manufacturers autonomously optimize product quality, reduce waste, save raw materials, and improve overall equipment effectiveness,

ProcessMiner is at the forefront of helping manufacturers combine IT and OT data to unlock hidden insights and deliver returns of more than $500K per year, per manufacturing line. The ProcessMiner platform automatically delivers improvements to overall operational effectiveness in the areas of availability, performance, and quality.

Manufacturing Needs to Stay Competitive in Today’s Ever-Changing Business Landscape

The manufacturing industry is changing rapidly, with artificial intelligence and technology playing an increasingly important role. Manufacturers that keep up with the changing landscape of technology and make it known that these advancements are being used will appeal to young workers. Potential employees want to see that the company is modern and keeping up with current trends, and investing to improve workers’ skills – factors that are important to many younger generations.

AI can provide a number of benefits to the manufacturing industry, including increased efficiency, improved quality control, and reduced costs. In addition, AI can help manufacturers train new employees and keep existing employees up-to-date on new technologies and processes. By investing in AI, manufacturers can stay competitive in today’s ever-changing business landscape.

Jeff Fulgham, ProcessMiner Business Advisor

Jeff Fulgham is a Senior Executive with over 40 years of experience in corporate strategy, strategic marketing, enterprise sales, and M&A. Jeff is passionate about innovation and aligning unique solutions with unmet customer needs to solve big challenges.

Jeff’s experiences include executive-level roles at General Electric, Banyan Water, a venture capital-backed startup, and Solenis, a private equity-owned carve-out. He has successfully led global marketing, services and research teams, acquisitions and divestitures, and is a recognized expert in addressing the global water crisis, helping major global clients optimize water & energy resources and reduce waste.