With the ability to digitize and automate virtually any process, digital manufacturing has become increasingly popular in recent years. However, there can be a number of factors that cause digital manufacturing to fail.

Inaccessible or irrelevant data, operational knowledge gaps, poorly defined processes, lack of standardization and inability to scale are some of the most common reasons digital manufacturing fails. For example, if a plant does not have access to real-time analytics and comprehensive data then it may struggle to keep up with the fast-paced nature of digital manufacturing.

It is important for any organization contemplating a switch toward digital manufacturing to make sure their team is fully educated on best practices and processes to ensure a successful transition.

Reason #1: Inaccessible or Irrelevant Data

One common problem manufacturers face is having too much data but not being able to harness it in an effective way. This can lead to uninformed decision-making due to information overload. Furthermore, this issue is often caused by problems with collecting and storing data as well as integrating new data sources. Collecting accurate and relevant data is essential for understanding how your factory operates currently so you can make improvements where needed.

Reason #2: Operational Knowledge Gaps

Another big reason digital transformations fail has to do with what’s known as operational knowledge gaps. This means there are inconsistencies between the way things are supposed to happen and the reality of what actually happens on the factory floor. These discrepancies often occur because processes haven’t been properly documented or understood from the outset. As a result, teams end up working in silos without adequate visibility into other areas of production. To avoid these issues, it’s important to establish clear lines of communication and accountability throughout your organization from the start.

Reason #3: Poorly Defined Processes

A third major obstacle occurs when organizations try to implement new technologies without first taking the time to understand their existing processes. You can’t just add new tech onto an existing system expecting it to work miracles if you don’t have a good foundation to build upon. It’s crucial to define all your processes clearly and document them before trying any sort of implementation project — otherwise, you risk developing mismatches between different systems down the road.

Reason #4 Lack Of Standardization

The next challenge arises when factories try to standardize their approach but lack company-wide coordination to do so successfully. Trying to achieve uniformity becomes much harder once the business starts to scale rapidly adding multiple locations and facilities into the equation. To counter this problem, manufacturers need to put forth concerted effort come standard protocols and practices everyone follows regardless of circumstances they face along the way.

Reason #5 Inability to Scale

And speaking of scalability, perhaps the biggest reason digital transformations fail has to do with the fact that these implementations simply are not designed with scalability in mind from the outset. Scalability is key when introducing digital solutions as companies can no longer afford to simply create a solution that works for their current needs—it must grow with the company and accommodate changing trends. Because of this, digital transformation plans must be made with scalability in mind from the start or else businesses might find themselves investing heavily in temporary solutions that waste both valuable time and money.

Now that we’ve covered the most common reasons why digital manufacturing implementations fail, let’s talk about what you can do to avoid them – short-term goals vs long-term goals and having achievable milestones along the journey.

Inaccessible or irrelevant data – When data is difficult to access or find, it can stall production and lead to errors.

When data goes missing or unorganized, digital manufacturing can quickly be thrown into disarray. Without accurate and up-to-date data, production can become stalled and errors can arise. Finding the right information in a timely manner allows for smoother operations and helps to ensure that the production process is efficient.

Additionally, having access to relevant data helps create solutions that are tailored specifically to the project at hand, thereby making the best use of resources available. It’s no wonder then why accessible and relevant data is key for those in digital manufacturing fields – it not only helps with efficiency but also creates solutions better suited for any given circumstance.

Operational Knowledge Gaps – If there are gaps in knowledge about how a digital manufacturing process works, it can cause problems down the line.

Operational knowledge gaps can be a challenging constraint when it comes to digital manufacturing. When operations teams lack the knowledge required to effectively manage these processes, it can lead to costly mistakes and hindrances (that are difficult to recover from).

This is why organizations must take proactive approaches to ensure that all operational teams have thorough and up-to-date training on their process workflow, from the factory floor workers to the senior leaders. Cultivating an environment of open communication, ongoing education, and feedback between departments can go a long way in closing potential operational knowledge gaps in digital manufacturing processes.

Poorly Defined Processes – If processes are poorly defined, it can lead to confusion and errors during production.

Poorly defined processes can be a major roadblock to successful digital manufacturing. When processes are not clearly laid out, staff can become confused and make mistakes that slow down or derail the manufacturing process entirely.

Establishing clear processes and procedures allows everyone involved in production to understand the workflow from start to finish. Encouraging team members to ask questions when encountering something unfamiliar will also help clarify a process and keep production on track. With improved processes, manufacturers can ensure their projects are completed quickly and with fewer errors.

Lack of Standardization – Without standardization, each manufacturer may produce products differently, which can cause compatibility issues.

When it comes to digital manufacturing, a lack of standardization can have a majorly negative impact. Every manufacturer may produce products differently if they do not have standardized processes in place, and this discrepancy can cause compatibility issues when combining parts from various sources.

This can lead to production delays, customer dissatisfaction, and a lack of coherence between departments. Standardizing processes is paramount for the success of any digital manufacturing strategy – without it, operations may come to a screeching halt due to incompatible components.

Inability to Scale – When a digital manufacturing process is unable to scale, it can limit growth and hinder productivity.

The inability to scale digital manufacturing can be a frustrating roadblock for a business. When production is unable to keep up with the demand of customers or requirements of the organization, it can be disastrous for a company’s growth and overall productivity.

It’s important to determine whether or not an existing digital manufacturing workflow is scalable, and if necessary make adjustments before expanding current efforts. Investing in strategies such as automation, design optimization, and agile manufacturing are all potential methods that manufacturers can use to make sure their processes are able to scale easily.

What to Do When Digital Manufacturing Fails

Digital manufacturing provides numerous benefits to manufacturers but it also comes with its own set of risks that must be managed properly in order for it to be successful. By understanding these risks and implementing the proper measures to address them, manufacturers will be better equipped to handle any potential issues that may arise from using digital manufacturing processes.

With the right approach and preparation, manufacturers will be able to enjoy the many benefits that come along with digital manufacturing while minimizing any potential problems they may encounter along the way.

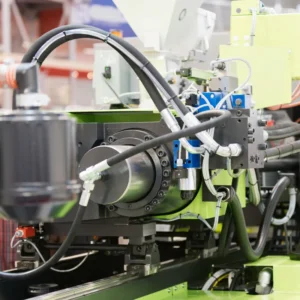

At ProcessMiner, our research and development team has developed a data science solution that has helped an F500 and one of the largest plastic injection molding manufacturers to reduce scrap rates by more than 50 percent. When ProcessMiner began this journey, we knew it was going to be a game-changer in the manufacturing industry. Fast forward to a few years later, we made a significant impact in the pulp and paper and plastics industries.

Our industry-leading autonomous control solution delivers process improvement recommendations and parameter control changes in real-time to the production line. Our platform ensures high-quality output while driving reductions in scrap, defects and waste commonly encountered in complex manufacturing processes.

Below are a couple of successful examples:

(1) ProcessMiner team developed a data science solution that helped an F500 plastic injection molding manufacturer to reduce scrap rates by more than 50 percent.

(2) Our artificial intelligence platform achieved unprecedented autonomous chemistry control for the tissue mill. Using a closed-loop controller in conjunction with quality parameter predictions, the mill was able to control its strength chemistry autonomously to ensure optimal chemical feed and adhere to target parameters. As a result, there was a 25% reduction in wet strength chemistry, a 33% reduction in wet tensile variation, and a 98% increase in target adherence.

Digital manufacturing offers a wealth of benefits for manufacturers looking to improve their production processes—but only if done correctly! While there are many potential causes of failure when working with digital manufacturing technology, there are also strategies available for avoiding them altogether if implemented properly from the start.

By ensuring that data quality is high, standards are enforced across departments or teams, and processes are established before starting any project—manufacturers can set themselves up for success with their next digital manufacturing endeavor!

Final Thoughts

In conclusion, digital manufacturing challenges are real and require a proactive approach to mitigate potential risks. Without proper data access, gaps in operational knowledge, well-defined processes, standardized procedures and the ability to scale up production, any digital manufacturing process may not only be inefficient but also result in costly errors down the line.

With the proper preparation and tooling, however, digital manufacturers can anticipate and address these challenges early on in order to ensure a smooth and successful production run.

To make sure your venture into digital manufacturing is successful, it’s important to understand each of the aforementioned challenges and put systems in place prior to getting started with any production process. This effort will pay off over time when all goes as planned without any unexpected hiccups.