AI for Plastics Manufacturing

Improve process quality, reduce scrap rates, and augment manufacturing efficiency with the ProcessMiner AI solution. Our plastics manufacturing software platform uses real-time analytics and autonomous process control to optimize plastic molding production, ensuring a more efficient, cost-effective, and sustainable manufacturing process.

Tackling Plastics Manufacturing Process Challenges

Plastic molding and forming are vital for producing high-precision components, but they face challenges that impact efficiency and quality. Our manufacturing process automation solution uses AI and machine learning to monitor and automate the plastic molding process, reducing scrap rates, increasing throughput and yield, and contributing to overall plant efficiency.

Our turnkey solution integrates seamlessly with existing IT/OT infrastructure, requiring no capital expenses or investment in staffing data scientists to deploy. Built from the ground up to address the top plastic molding challenges, use our platform’s autonomous control to:

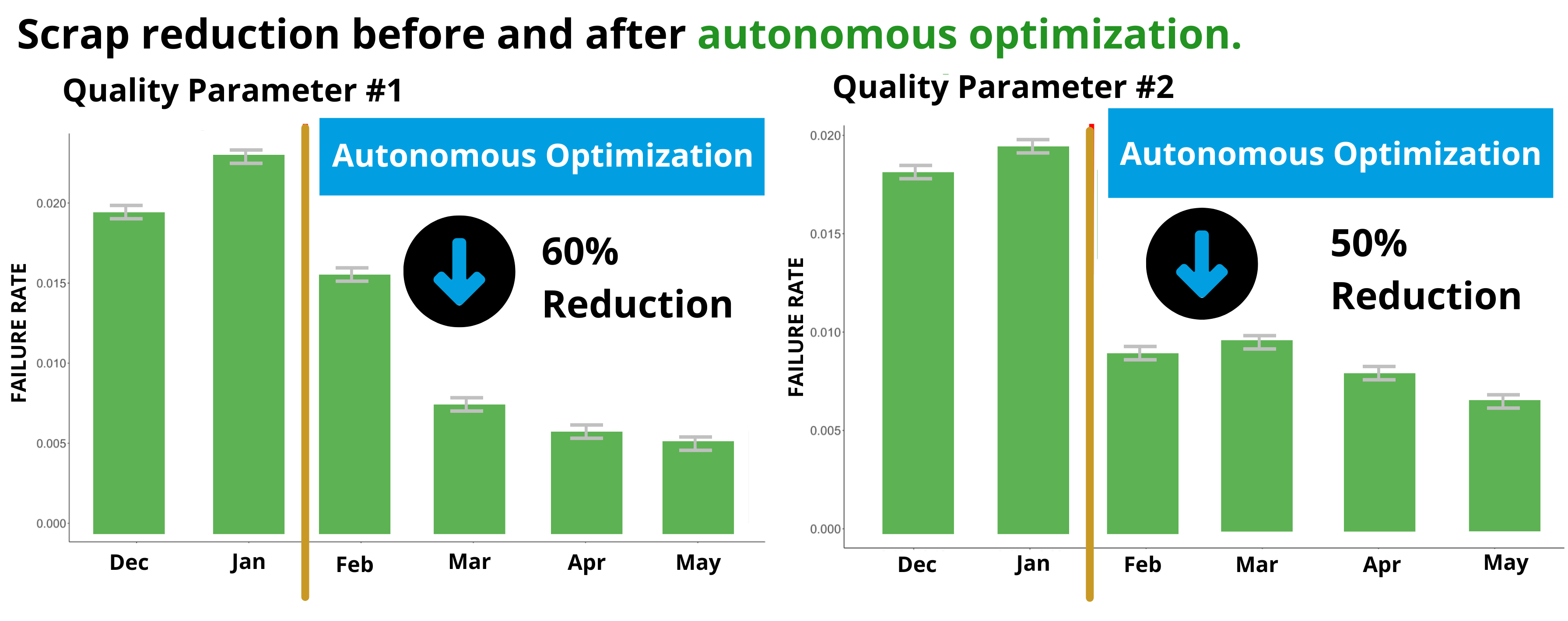

Reduce Scrap

Analyze historical and real-time production data to predict end of run quality results and mitigate issues or conditions before they impact output quality, producing a higher yield.

Enhance Quality Assurance

Adjust machine critical control elements in real-time to produce in-spec results more consistently and minimize quality variance.

Streamline Production Runs

Monitor and adjust set points and critical stages of the molding process, from pellet molding to mold cooling, by using AI to streamline production. Make each production run more efficient, shortening cycle times and boosting throughput.

Improve Productivity

Automate manual monitoring and troubleshooting tasks to ensure precise and timely set-point control, freeing up plant operators to focus on other production activities.

Mitigate Supply Chain Disruptions

Make more efficient use of raw materials per production run, minimizing the impact on production due to shortages in procurement and transportation logistics delays.

Ensure Sustainable Practices

Use AI to promote more eco-friendly materials and efficient plastic production processes to reduce scrap/waste, energy, and carbon footprint consistently across all plastic molding machines.

eGuide: 5 Ways AI Streamlines Plastic Molding Processes

Advanced technologies like artificial intelligence (AI) are redefining traditional plastic molding processes, enabling you to do more with less. When coupled with industry best practices and institutional knowledge, AI can increase efficiencies, lower scrap waste, decrease defects, and more.

Download our eGuide to explore five critical ways AI can transform your plastic molding processes, empowering you to meet and exceed your operational objectives.

The Impact of AI Automation in the Plastics Industry

Reducing defects and variability in quality is crucial in plastics manufacturing, requiring a more proactive, timely, and precise quality control process. Use our platform to uncover the insights hidden in your production and quality test data to prevent issues before they affect output.

Want to explore the full impact of AI on plastic molding automation?

Get the infographic to understand the business value.

Enhance Your Plastics Manufacturing Process

Experience significant improvements across various molding processes with the versatile ProcessMiner AI solution, tailored to meet your specific plastics manufacturing needs and operations.

Plastic Injection Molding

Automate control adjustments to reduce defects and ensure consistent quality output.

Thermoforming

Improve process control for better material usage, reducing cycle times and enhancing product quality.

Compression Molding

Streamline the molding process for complex parts, improving efficiency and reducing cycle times with consistent quality.

Extrusion Blow Molding

Enhance material distribution and wall thickness uniformity, minimizing waste and improving product consistency.

Rotational Molding

Gain precise control over temperature and rotational speed, ensuring even material distribution and reducing cycle times.

How ProcessMiner Improves Quality Management Processes

Our AI manufacturing process tracking software streamlines production cycles by optimizing each phase of the molding process.

Step 1: Data Integration

Our platform ingests historical and real-time process data from the historian, sensor, and QA results to support data-driven insight and decision-making.

Step 2: Predictive Analytics

Analyzing historical patterns and trends, ProcessMiner forecasts plastic molding end-of-run outcomes to proactively identify out-of-spec results.

Step 3: Operational Recommendations

Based on analytic results and root cause analysis, our platform delivers prescriptive set point corrective actions to maintain optimum output results and within tolerance specs.

Step 4: Autonomous Adjustments

Step 3 recommendations can be executed via our closed-loop system without the need for manual intervention, ensuring real-time corrections are made in a timely manner to improve manufacturing efficiency.

Step 5: Continuous Optimization

The platform’s machine learning based adaptive and self-learning capability improves results over time without requiring data scientists to retrain their models.

The Benefits of AI-Driven Manufacturing Process Automation

Refining plastic molding processes helps you gain benefits beyond quality assurance.

Optimized Operations

Real-time process parameters maximize efficiency and equipment longevity.

Improved Quality Assurance

Continuous monitoring and closed-loop control element adjustments ensure production consistency and reduce defect rates.

Increased Productivity

Timely adjustments to critical process set points minimize quality deviation and optimize output per production run.

Enhanced Supply Chain Resilience

Ability to analyze inconsistencies in raw material batches from the same supplier or across suppliers.

Augmented Product Development

Empower R&D to aggregate and analyze volumes of data output from testing multiple product variants to quickly identify differences and key insights, which shortens the innovation cycle.

Increased Sustainability and Compliance

Reduced raw material consumption and reduced scrap and waste support the achievement of sustainability goals and regulatory compliance.

Why ProcessMiner for Plastics Manufacturing?

Harness the power of state-of-the-art technology designed from the ground up with an in-depth understanding of the dynamic nature of plastics manufacturing. Our solution offers proactive, data-driven decision-making, real-time insights, and timely corrective actions.

Turnkey Solution

- Accelerate time to value

- Integrate with existing infrastructure

- SaaS solution, no CapEx required

Advanced AI and Machine Learning Capabilities

- Adaptive and self-learning analytical models

- Unique proprietary algorithms

- Specifically configured for each machine

Automated Smart Manufacturing

- 24X7 monitoring and corrective action

- Data-driven decisioning

- Delivers virtual measurement of quality impossible to measure manually in real-time

Real-World Plastics Manufacturing Application

How We Helped this Plastic Processor Reduce Scrap Rates by 25%

Facing scrap rates upwards of 20%, this plastic manufacturer turned to ProcessMiner to determine scrap root causes and address process improvement opportunities. After analyzing historical and real-time process data from the plastic injection molding machine, ProcessMiner reduced scrap rates by 25% and drove annualized six-figure operational savings to the manufacturing operation.