Pulp & Paper

The next big AI steps into the

Pulp & Paper industry

Real-time analysis delivers proactive process control.

OPTIMIZE USAGE OF RAW MATERIALS

REDUCE PRODUCTION COSTS

REDUCE QUALITY VARIATION

IMPROVE PRODUCTIVITY

Addressing Top Pulp & Paper Challenges With Artificial Intelligence

Put your data to work and solve complex pulp and paper manufacturing challenges.

Predict Quality Issues

Identify Variability

Drive Optimum State

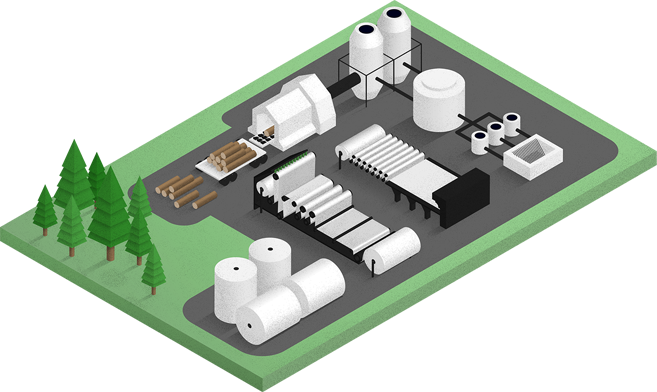

Smart Manufacturing and Autonomous Control for Pulp and Paper Manufacturing

Critical to optimizing the performance of plant operations and reducing quality variations in pulp and paper manufacturing is proactive and accurate process control. Smart technology is being adopted by the pulp, paper, and packaging industries; this digital transformation in manufacturing reduces the consumption of raw materials, and process variability, drives down costs, increases throughput, and gains a competitive edge with customers.

The ProcessMiner AI-enabled platform delivers process improvement recommendations and optimal control parameters in real-time to your pulp and paper production line. Through our predictive machine learning and artificial intelligence systems, online recommendations are sent for autonomous proactive control. Our platform ensures reductions in cost, scrap, and defects commonly encountered in pulp and paper manufacturing processes.

Real-time Pulp & Paper Quality Improvement Recommendations

Recognize material return on investment and capture sustainability improvements.

Actual ProcessMiner™ Business Cases

Packaging

Savings Per Ton

Savings Per Machine (Per Year)

Variable Cost Reduction

%

Tissue

Savings Per Ton

Savings Per Machine (Per Year)

Variable Cost Reduction

%