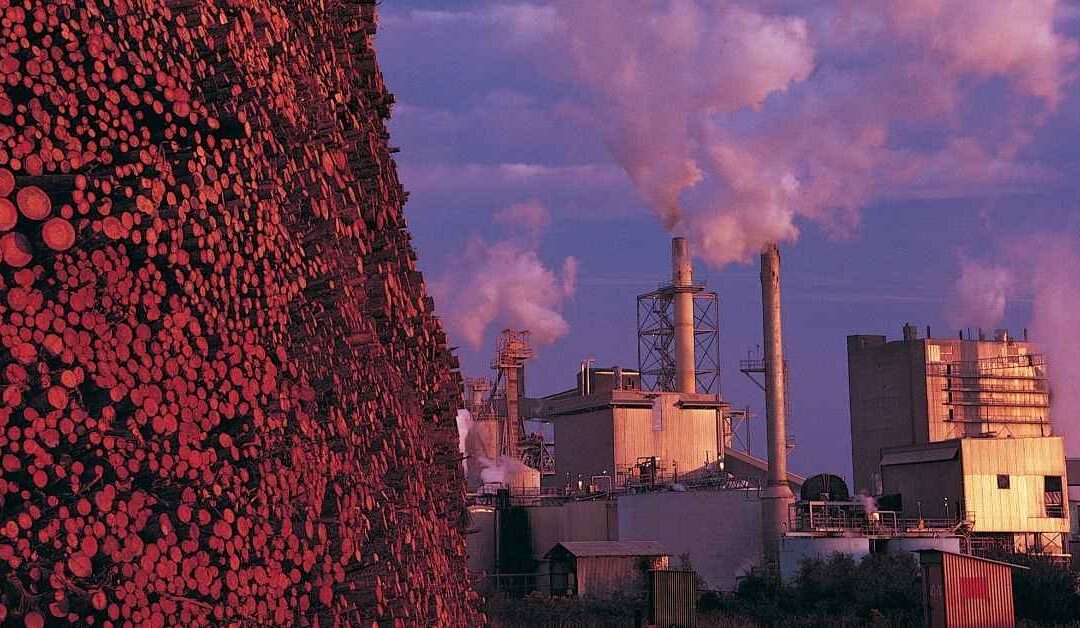

Using artificial intelligence (AI) in pulp mills, which have traditionally been paper factories that employ human decision-making almost completely, is one of the ways to lower costs. This article explains why AI is crucial for a successful pulp and paper production.

New Levels of Productivity in Pulp and Paper Operations

Global production of paper and cardboard totals more than 400 million metric tons each year.

Digital technologies including machine connectivity, intelligent automation, and advanced analytics, enable new levels of productivity in pulp and paper operations by leveraging large quantities of production data to deliver better insights and outcomes.

Successful digital innovators are seeing throughput gains of 5 to 10 percent, yield gains of up to five percentage points, and significant savings on materials, chemicals, and energy.

For the industry, this represents a $4 billion to $6 billion opportunity, and the value is achievable here and now. [McKinsey, Aug 2021] That said, most manufacturers are just beginning to see its full potential on their operations.

Pulp & Paper Manufacturers Should Embrace Digital Technologies to Keep Up with the Competition

Thanks to digital technology, pulp & paper plant managers will know exactly when equipment needs servicing instead of having to wait until it breaks down. AI is being used to identify pulp quality problems up to eight hours ahead of time. This gives pulp producers enough time to make adjustments before they lose yield or even cause a pulp spill.

In addition, artificial intelligence can be used in pulp and paper plants for automated processes requiring little human assistance. This allows pulp & paper plants to cut down on their labor costs as well as improve safety by eliminating tasks that employees perform in hazardous environments.

Pulp Manufacturers Face Serious Challenges in Adopting Digital Technologies

Three-dimensional imaging provides information about pulp qualities by measuring fiber length, freeness (lining) and specific gravity instantly at the press. The pulp testing equipment sends this information wirelessly to an outside computer where it can be viewed in real-time at mills or companies around the world using web terminals with 3D pulp data.

Virtual reality allows pulp producers to see virtual pulp testing results before they set up lab equipment or make changes at pulp machines. This means they can adjust pulp production settings to avoid pulp quality deviations without the need for actual testing and adjustments, which saves both time and money.

Despite the potential, pulp manufacturers face serious challenges in adopting digital technologies and systems. A typical pulp mill’s production of pulp is around 300,000 tons per year and they typically possess hundreds of pulp machines that produce pulp and paper products on a daily basis.

The need to maintain compliance with environmental standards also affects their ability to incorporate new digital technologies into their existing infrastructure. Pulp producers must focus more on how they can improve their pulp quality before thinking about integrating robotics or AI into their pulp & paper process as these are costly investments.

Impediments aside, pulp manufacturers should embrace digital technologies and find ways to integrate them into their pulp & paper production processes in order to improve product quality and lower costs while enhancing pulp recovery rates.

The pulp and paper industry is one of the largest industrial sectors in the world, worth more than $1.5 trillion. Pulp mills must remember that if they want to increase their market share in a highly competitive pulp & paper industry, embracing digital technologies is the only way forward.

Learn how the ProcessMiner platform uses real-time artificial intelligence to help reduce energy consumption, raw materials, chemical usage and cost. See our quick “How it Works” video.