ProcessMiner™ Insights

The latests thought leadership, manufacturing AI trends and research from ProcessMiner™

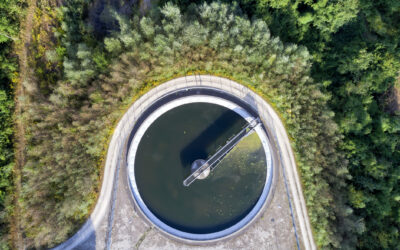

How to Drive Innovation and Compliance in Wastewater Treatment Today

The wastewater treatment sector is facing a significant regulatory shift. Stricter laws and regulations have increased the pressure on wastewater treatment plants to adapt and evolve. Recent amendments in EPA guidelines focusing on nutrient removal have highlighted...

Why Addressing Environmental Challenges Requires Advanced Wastewater Treatment Solutions

Governments and environmental agencies worldwide increasingly recognize the urgent need to tackle water-related issues. For instance, the EPA emphasizes the critical role of Wastewater Treatment Plants (WWTPs) in mitigating these challenges. With the advent of AI and...

Polymer Dosing in Wastewater Treatment: Getting it Right

Achieving the right balance in polymer dosing remains a nuanced and complex task for wastewater treatment professionals. This dynamic process is significantly influenced by the constantly changing nature of wastewater inflow and composition. Traditional manual dosing...

Is Sludge Cake Density Hurting Your Bottom Line?

Over the years, more effective wastewater treatment methods have significantly reduced sludge cake volume. Today, the average volume of sludge is just 1% of influent wastewater treated, which drops to 0.5% with dewatered sludge. However, even with these relatively...

Revolutionizing Plastics Manufacturing with Deep Learning and AI

In the evolving landscape of plastics manufacturing, the integration of deep learning and AI technologies is redefining standards for quality control, operational efficiency, and sustainability. This transformative approach goes beyond enhancing production processes;...

AI-Driven Process and Quality Optimization in Modern Wastewater Treatment Facilities

In the vast tapestry of global challenges, the efficient and sustainable management of water stands out as one of the most pressing. As water scarcity looms and treatment processes grapple with increasing demand and rising costs, the treatment of wastewater becomes a...

Leading the Way in Modern Manufacturing: How Real-Time Data Transforms the Shop Floor

In the age of digitalization, real-time data is transforming the manufacturing landscape. With insights provided at the speed of thought, manufacturers can make informed decisions, refine processes, and adapt to rapidly changing conditions. The integration of...

Driving Continuous Improvement in Manufacturing for Better Business Value

In the rapidly changing industrial landscape, continuous improvement in manufacturing has become a prerequisite for sustainable success. This concept refers to an ongoing effort to enhance product quality, streamline operations, and optimize performance across the...

Transforming the Shop Floor Through Data: Harnessing AI-Enabled Manufacturing Optimization

From the steam-powered looms of the first industrial revolution to the automated production lines of today, the manufacturing sector has continually evolved. In this ever-evolving saga of industrial progress, the fourth industrial revolution brings with it the...

Deep Learning is Reinventing Quality Control in the Manufacturing Industry

The manufacturing industry has long relied on quality control to ensure the safe, efficient, and high-quality production of goods. However, recent advancements in deep learning and machine learning technology have transformed traditional quality control methods,...

AI-Driven Strategies for Sustainable Wastewater Management

In the current landscape of environmental conservation, sustainable wastewater management is emerging as a critical priority. At the forefront of this movement are AI-driven strategies that are reshaping how wastewater is treated, making the processes not only more...

Elements to Consider Before Digitizing Your Factory for Autonomous Manufacturing

As the manufacturing industry evolves, autonomous manufacturing is becoming a reality for many businesses. But manufacturers must first digitize their factories before they can reap the benefits of autonomous manufacturing. Digitization involves integrating...

The Importance of Industry 4.0 in Manufacturing Plants

Industry 4.0 is the fourth industrial revolution that is changing the way we manufacture products. It is characterized by the use of interconnected technologies such as the internet of things (IoT), artificial intelligence (AI), and machine learning (ML) to optimize...

Top 5 Reasons Digital Manufacturing Fails

With the ability to digitize and automate virtually any process, digital manufacturing has become increasingly popular in recent years. However, there can be a number of factors that cause digital manufacturing to fail. Inaccessible or irrelevant data, operational...

Harnessing AI for Enhanced Wastewater Quality Monitoring and Control

In the realm of wastewater management, the introduction of Artificial Intelligence (AI) is ushering in a new era of precision and efficiency. This technology is not just an upgrade; it’s a complete overhaul of how we monitor and control the quality of wastewater. The...

Benefits of AI and Continuous Manufacturing

Achieving success as a manufacturer requires staying ahead of the competition. This means continually innovating, investing in resources, and leveraging new technology—including Artificial Intelligence (AI) and continuous manufacturing. In this blog post, we'll take a...

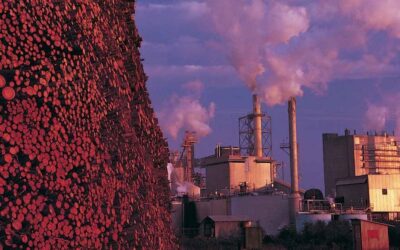

Challenges and Benefits of AI-Driven Autonomous Chemistry Optimization for the Pulp & Paper Industry

Today, pulp and paper manufacturers are under immense pressure to improve efficiency and cut costs. One way they address these challenges is by turning to AI-driven autonomous optimization. AI-driven autonomous optimization can help paper and tissue manufacturers...

How to Attract a Younger Workforce in the Manufacturing Industry: The Challenge of Perceptions

The manufacturing industry is facing a skilled labor shortage. As the industry looks to the future, one of its biggest challenges will be attracting a younger workforce. The problem is that the current perception of manufacturing jobs is inaccurate. Many people -...

Bridging the Skilled Labor Gap in the Manufacturing Industry

The skilled labor gap is a real and pressing concern for manufacturers. As baby boomers retire or leave the workplace, there are simply not enough skilled workers to replace them. This is expected to have a major impact on the manufacturing industry as companies...

AI Supporting Effective Wastewater Operations

When it comes to wastewater operations, having accurate and timely data is essential for efficient decision-making. While humans are capable of collecting and analyzing this data, artificial intelligence (AI) can help take things to the next level. In today's...

Data Science: How It Can Potentially Transform the Manufacturing Industry

Over the past few decades, the manufacturing industry has gone through multiple stages of transformation aided by four industrial revolutions. Now we are on the cusp of another major revolution led by data science and artificial intelligence. Though data science is...

Big Data and Industry 4.0: Significant Cost Savings in the Pulp and Paper Industry

In the pulp and paper industry, there is a lot of excitement about the potential of big data analytics and Industry 4.0 to optimize plant operations further. Driven by global demand, sustainability efforts, an aging workforce and margin pressures, the time has come...

Using Artificial Intelligence to Speed Up Paper Production and Lower Your Pulp & Paper Manufacturing Costs

Using artificial intelligence (AI) in pulp mills, which have traditionally been paper factories that employ human decision-making almost completely, is one of the ways to lower costs. This article explains why AI is crucial for a successful pulp and paper...

Benefits of Sustainable Pulp & Paper Manufacturing

Interesting fact: there are currently no sustainability standards for pulp and paper mills even though sustainability is becoming more important globally. Another interesting fact: It takes more than 400 years for a tree to remove its carbon footprint. Why...

The Future of Pulp & Paper Manufacturing

The pulp and paper industry is one of the largest industrial sectors in the world. Over the past two decades, it has experienced considerable change, including digital technology advancements, environmental factors, rising energy and labor costs, sustainability...

The Evolution and Required Transformation of Statistical Process Monitoring

In Industry 4.0, there is a need for automated diagnosis of process monitoring alarms along with root cause determination and process adjustment. Computationally intensive and adaptable approaches such as those incorporated into ProcessMiner software are required for...

Three Common Misconceptions About AI in Manufacturing

Artificial intelligence (AI) and machine learning (ML) are creating quite a name for themselves in the manufacturing industry and for good reason. Both AI and ML are helping manufacturers use factory data to streamline operations, improve processes and make better...

Manufacturing’s Perfect Storm

US Manufacturing Supply Chain Unprepared for Record Surge in Demand By: Tom Tulloch, Chief Commercial Officer, ProcessMiner™Manufacturing is forecast to come roaring back in the second half of 2021, according to many leading indices. This is fantastic news for...

Bringing Industry 4.0 to You

The Industrial Revolution paved the way for the life we know today and far surpassed the era of simplistic conveyor belts and heavy manual surveillance. Production lines employ machinery and humans alike. Industries have always stepped up with technological advancement and thereby use a plethora of devices designed and produced to meet specific tasks on factory grounds.

Variability Reduction: Why Important To Manufacturers?

A real-world dataset is provided from the pulp-and-paper manufacturing industry. The dataset comes from a multivariate time series process. The data contains a rare event of paper break that commonly occurs in the industry. The data contains sensor readings at regular time-intervals (x’s) and the event label (y).

Contact Our Data Science Team

Fill out the form below and we’ll get back to you, or contact us by phone to speak to a miner today.

Have a project in mind?

For more information, download our brochure. We’ll reach out to you!

U.S. Headquarters

75 Fifth Street NW

Suite 2505

Atlanta, GA 30308

+1 (678) 463-5799

info@processminer.com

International

INDIA

FINLAND

Oy ProcessMiner Ab

Otakaari 5

02150 Espoo

+358 400 450 748

jvanska@processminer.com