Company

F500 Plastic Injection Molding Manufacturer

Challenge: Dealing With Unusually High Defect Rates

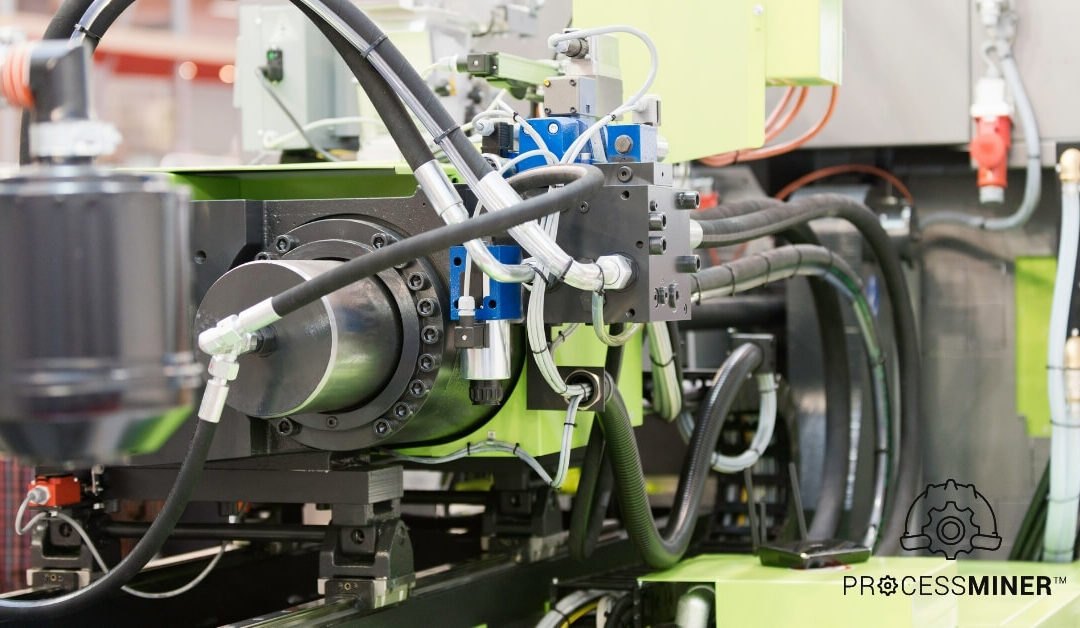

A leading plastic injection molding manufacturer was experiencing high defect rates in a medical specialty plastic vial product. The manufacturer solicited the help of ProcessMiner to identify and mitigate the root causes associated with the defect rates.

Solution: Using AI To Find Out Scrap Rate Root Cause

Recognizing the potential to leverage AI for plastics manufacturing process optimization, together the manufacturer and ProcessMiner collaborated on a pilot project. The primary goal was to assess if ProcessMiner’s AI platform could effectively monitor, predict, and prevent defects that were increasing scrap rates in excess of 20% above the company average.

The project began with an extensive offline data analysis to evaluate the data quality accurately from the pilot machine. This critical step enabled a detailed understanding of essential manufacturing quality parameters and control elements.

Within the first 90 days, ProcessMiner’s AI platform analyzed data from more than 300 sensors on the injection molding machine. This analysis pinpointed two specific defect types responsible for a majority of the scrap in the specialty bottle production.

Using these insights, ProcessMiner’s AI platform provided targeted recommendations for adjusting key parameters such as temperature and pressure settings. These recommendations were crucial for refining production quality.

Results: 6-Figure Savings and Improved Scrap Rate

Implementing ProcessMiner’s AI-driven recommendations reduced scrap rates by 25%, significantly enhancing operational efficiency. The pilot also equipped the manufacturer with advanced tools for real-time monitoring and automated corrective action. These tools facilitated proactive adjustments through prescriptive parameter control recommendations automatically transmitted to the plastic injection machine control systems.

ProcessMiner’s introduction of autonomous control that allowed for automatic adjustments to production set points via IoT technology. This closed-loop system and autonomous control platform streamlined operations, consistently reduced defects, and maximized productivity, resulting in a higher first-pass yield.

Throughout the pilot, ProcessMiner’s AI platform autonomously adjusted the plastic injection molding machine settings at the start of each manufacturing shift. This consistency significantly reduced production variability and increased stability.

By autonomously maintaining optimal machine settings, the platform helped create a more predictable and efficient manufacturing environment, ultimately yielding annualized six-figure operational savings for the company.