Solenis OPTIX™ Applied Intelligence is our exclusive partner in modernizing the pulp and paper industry, leveraging cutting-edge AI-driven autonomous solutions to optimize processes, reduce waste, and achieve unprecedented operational efficiency.

Company

North American Tissue and Towel Producer

Challenge: Inefficient Chemistry Dosage Scheme

A North American tissue and towel producer was interested in reducing raw material consumption while optimizing wet tensile quality. The mill employed an inefficient dosage scheme for wet-strength chemistry. The dynamically changing nature of continuous manufacturing and the periodic reel-to-reel quality measurement environment of tissue-making presented operators with a challenge for manual optimization. This prompted the mill to search for an autonomous control solution built for the pulp and paper industry.

Solution: Optimizing Chemistry Dosage With Solenis OPTIX™ Applied Intelligence

The mill implemented OPTIX an AI and ML, predictive analytics platform with autonomous control capabilities. OPTIX generates a virtual measure of wet tensile quality in real time and uses machine learning capabilities to remain robust and accurate in the face of changing machine conditions. Leveraging artificial intelligence (AI) to make data-driven process adjustments, the wet strength chemistry dosage is finely tuned to drive wet tensile quality to the target.

Results: Achieving Immediate Cost Savings

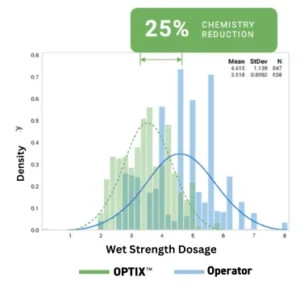

Over a six-month period using OPTIX, the mill achieved a 25% reduction in wet strength chemistry usage through autonomous control.

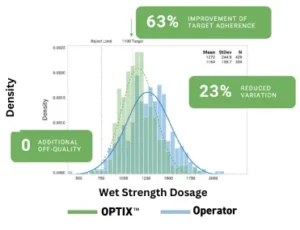

The autonomous control algorithms recommended adjustments to wet strength chemistry dosage to ensure optimum target adherence to the wet tensile quality parameter. OPTIX optimized wet tensile quality by reducing quality variation by 23% and increasing target adherence by 63% all while avoiding off-quality production.

Note: This case study highlights the strategic partnership between ProcessMiner and Solenis in pulp and paper continuous manufacturing as strategic partners. ProcessMiner’s AI-driven solutions also extend beyond the pulp and paper industry, offering optimization in various sectors.