Author: Chitta Ranjan, Ph.D., Director of Science, ProcessMiner, Inc.

Industry: Chemicals, Pulp & Paper

Overview

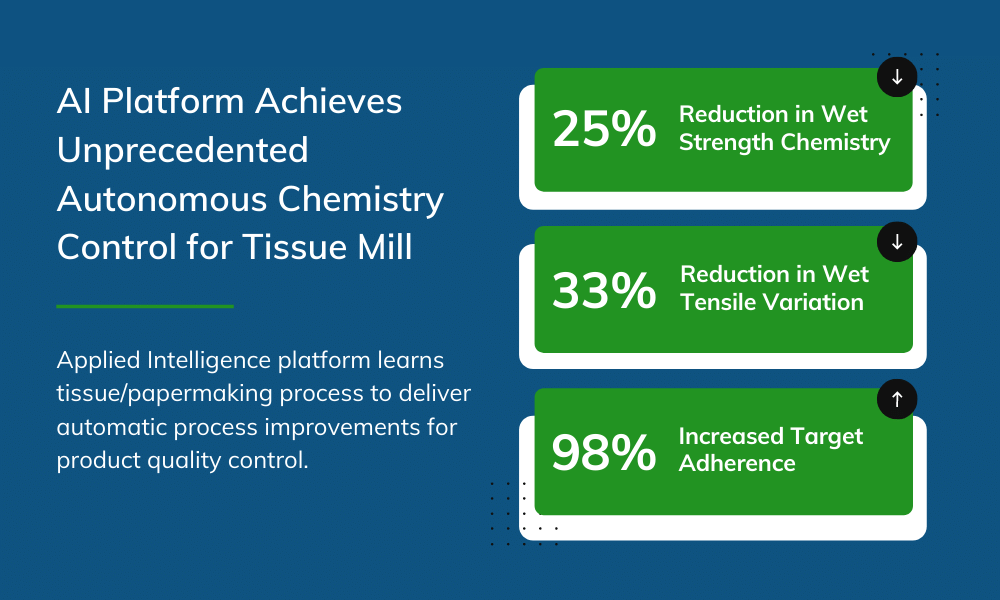

The goal of this project was to autonomously control part of a tissue mill’s continuous manufacturing process using artificial intelligence and predictive analytics to reduce raw material consumption while maintaining the product quality with specification limit.

Predictive analytics uses a manufacturing machine’s historical data to predict process outcomes. Through machine learning and artificial intelligence, these models continue to learn, adapt and evolve, providing the user with accurate information that can drive better decisions.

Challenge

It is difficult to learn a multitude of relationships in a complex manufacturing environment. Typically, an operator uses his or her past experiences in determining how to regulate the dosage of a raw material with:

- preferred minimum raw material consumed, while

- keeping the product quality within range

The challenge, therein, lies with the operator’s ability to act quickly with the dynamically changing manufacturing processes, and deliver continuous process improvement with autonomous chemistry control.

Solution

This is where the ProcessMiner AutoPilot real-time predictive system comes in and solves the problem, making recommendations and prescribing solutions. In doing this, it minimizes raw materials and reduces costs while maintaining both speed and product quality.

ProcessMiner’s AI platform is a cloud-based system that utilizes information, including:

- Physical tissue/papermaker property measurements

- Tissue/papermaking process knowledge

- System ‘meta-data’ to mathematically model the tissue/papermaker system

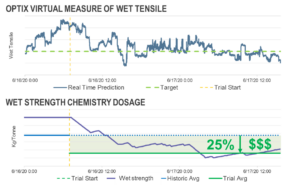

The information generated by this continuously-learning model is then used to accurately predict key performance indicators (KPI) of the tissue/paper machine, and therefore, provide actionable insights.

The Solenis OPTIX ProcessMiner AutoPilot platform is designed to be an adaptive and evolving artificial intelligence system, allowing it to automatically and simultaneously learn these relationships. The adaptive analytics system accurately learns complex variable relationships in pulp and paper manufacturing processes and yields a digital measure of product quality.

For example: every time the system hits a new data point, it runs an orchestration (sequence of steps) series of processes, and in turn, updates the AI platform to adapt and evolve, always morphing to holistically make recommendations in real-time.

During the onboarding process, the ProcessMiner system loads up to one year of historical data, uses that past data to immediately initialize and train its artificial system so it is ready to go as soon as it is launched.

About the ProcessMiner AutoPilot adaptive and evolving model: Tissue/Paper manufacturing is a complex, continuous process that slowly and sometimes abruptly changes over time.

Example: When conditions in the complex tissue/paper manufacturing processes change over time due to parameter control variations (e.g. changes in raw materials or machine speed) it’s difficult to predict the quality of the produced product ahead of lab tests and often leads to machine operators making reactive control adjustments.

- These scenarios lead to two considerations, namely the predictive model needs to be updated frequently and historical data quickly becomes obsolete

- Thus, a continuously-evolving and adaptive model is required

- The ProcessMiner AutoPilot predictive model evolves over time as more data is collected

- With new data streaming, the old data slowly loses its relevance

- The prediction system is built such that it automatically uses the knowledge gathered from the old data and combines it with the new data to construct an evolved (a relearned and more accurate) model

Additionally, the prediction system self-adapts to a process change. For the model adaptation, we perform the best prediction model selection, and its retuning, periodically and on-demand.

- The periodic runs are to ensure nothing is missed by the triggers

- The on-demand is triggered automatically whenever a process shift is detected

- Data with measurement errors are identified in real-time using F-tests and are isolated from the training data

- Both of the above features are computationally intensive

- To deploy them in real-time, we parallelized the processes through multiple processing units

- The parallel processing enables the delivery of accurate predictions in real-time every 30 seconds.

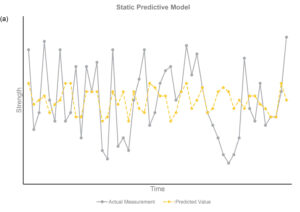

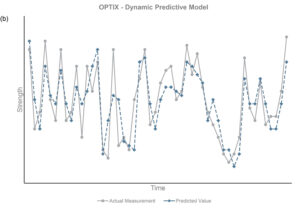

The charts throughout this case study show the outcome of a predictive model that uses an off-the-shelf approach without considering the unique characteristics of the tissue/papermaking process compared with a model using a tailor-made, advanced approach such as the one discussed previously. The oversimplified model depicted on the left does not mirror the true process, while that on the right considers the complexity of the tissue/papermaking process and clearly delivers predictions that are more accurate.

- A predictive model using poor prediction techniques that oversimplify the process (left)

- A predictive model with the same data utilizing advanced techniques capable of handling paper machine process data (right)

Predictive Model Accuracy: An accurate model provides predictions close to the actual value most of the time. The absolute value of the prediction, minus the test value, should be close to zero. Prediction accuracy must also be measured in real-time to instill confidence in users acting on the predictions. One method to evaluate prediction accuracy in real-time is to use a control chart to monitor the difference between actual and predicted values.

What makes the platform unique?

- Predictive soft sensor

- Machine learning

- Application expertise

- Model diagnostics

- Insight to influential process variables

Results

The results are a manufacturing game-changer. Autonomous manufacturing using AI with machine learning allows for improved product quality, optimized use of raw materials with reduced water and energy consumption.

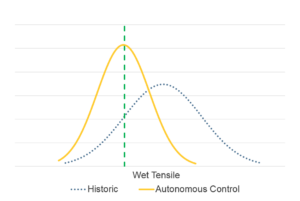

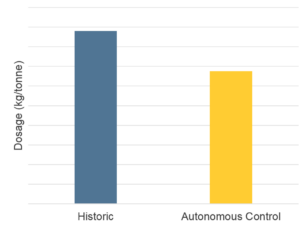

Using a closed-loop controller in conjunction with quality parameter predictions, the mill was able to control its strength chemistry autonomously to ensure optimal chemical feed and adhere to target parameters.

As a result of the artificial intelligence platform, the tissue mill achieved unprecedented autonomous chemistry, allowing for:

- Besides Wet Strength, Also Reduced Dry Strength Chemistry by 25%

- Grade ~30% Wet Strength Chemistry