Company

North American Virgin Coated Paper Board Mill

Challenge: Inefficient Quality Tests Result in Reactive Control and Chemistry Overdose

A North American virgin-coated paper board mill was interested in optimizing wet strength resin (WSR) consumption while maintaining wet tear quality. The dynamically changing nature of paper manufacturing presented operators with a challenge for manual WSR optimization. Additionally, delayed or erroneous quality tests caused mill operators to reactively control and overdose WSR, prompting the search for an autonomous chemistry optimization solution designed for the pulp and paper industry.

Solution: Incorporating AI-Driven Control Loop

The mill implemented Solenis OPTIX™ Applied Intelligence, powered by ProcessMiner. It’s a machine-learning, predictive analytics platform with autonomous control capabilities. The solution generated a real-time, virtual measure of wet tears and incorporated an AI-driven control loop to optimize the associated chemistry program. Machine learning was also used to ensure the quality measure remains accurate.

Results: Achieving Immediate Cost Savings

Complete autonomous chemistry control: OPTIX optimally controls wet strength chemistry for all the customer’s grades. Mill operators have embraced AI-autonomous control as a new tool to control wet strength chemistry.

Optimized chemistry dosage: Machine learning enables OPTIX to drive the WSR to the dose required to maintain wet strength quality, even during process changes. Mill operators no longer need to make knee-jerk reactions to quality tests while management takes comfort in knowing OPTIX is administering the correct amount of WSR for the process.

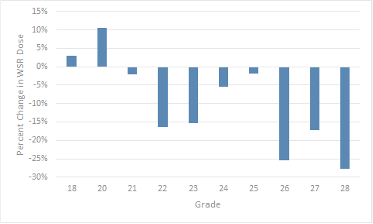

By allowing OPTIX to make decisions about WSR dosage, the mill can optimize dosage for each grade. An average dosage reduction of 18% across the heavy-weight grades was achieved by using OPTIX.

Focus on quality: Customized algorithms allow OPTIX autonomous control to drive quality to target specs. Since its installation, OPTIX has improved or maintained wet strength target adherence while producing no additional rejects. During upset conditions on a few light weights, OPTIX proactively increased WSR dosage to ensure wet strength quality persisted. The improved quality compliance has satisfied the quality control department and eliminated petitions from the quality manager.

Disclaimer: This case study highlights the strategic partnership between ProcessMiner and Solenis in pulp and paper continuous manufacturing as strategic partners. ProcessMiner’s AI-driven solutions also extend beyond the pulp and paper industry, offering optimization in various sectors.