Cement

Building Materials & Cement Manufacturing

Driving performance with your data can leverage your AI to heightened capabilities

PREDICTIVE MODELING

IMPROVE PRODUCTIVITY

REDUCE COSTS

CONTINUOUS IMPROVEMENT

ProcessMiner™ AutoPilot

Achieve Industry 4.0 SMART Factory objectives for your cement manufacturing operations.

IMPROVE ENERGY PERFORMANCE

IMPROVE INDUSTRIAL PROCESSES

OPTIMIZE AND MAXIMIZE ENERGY

DETECT ANOMALIES

Smart Manufacturing and Autonomous Control for Cement Manufacturing

The cement industry has been manufacturing products using the same recipes and same processes for decades. Unfortunately, Cement remains one of the most energy-intensive manufacturing fields in manufacturing. The cement industry is under significant societal pressure to find new ways to adopt more environmentally sustainable manufacturing processes. That is where AI can help.

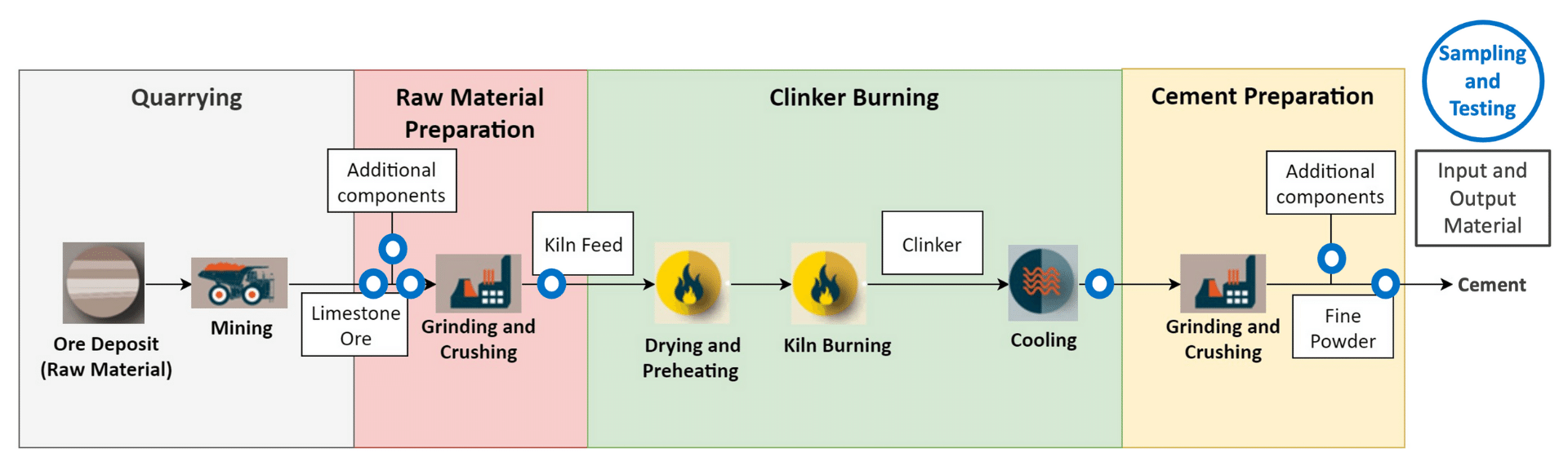

While the manufacturing process is fairly straightforward (see diagram below), variability in the process can lead to waste and inefficiencies. Most Cement companies are now looking to apply Artificial Intelligence to their process to drive compliance towards the most optimal recipe and the most efficient operating environment for cement production.

Much can go wrong however and that is where AI can help. ProcessMiner can automate ideal set points and optimize the cement manufacturing process from beginning to end (Quarry to Customer).

The ProcessMiner platform uses Intelligent AI to quickly and accurately apply predictive analytics to process data, and deliver prescriptive process control recommendations for autonomous control purposes. Our library of data models is able to quickly identify variability in the manufacturing process and automatically apply process parameter control changes to achieve the most efficient outcomes possible.

ProcessMiner AI for Cement Manufacturing Features & Benefits:

Features for Cement Industry:

- Data collection and fusion for optimization at every stage of the cement manufacturing process:

| Temperature | Pressure | Speed | Flow rates | Fuel consumption |

- Advanced Monitoring for Engineering and Operational performance purposes

- Root Cause Analysis – to identify what happened and why

- Predictive Analysis

- Prescriptive Recommendation

- Autonomous Optimization – Auto Pilot for automated process control variables using edge computing, IIoT devices and DCS control commands

- After the Intelligent AI platform is applied to the cement manufacturing process the Cement Supplier achieves the following benefits:

-

- Optimized raw material mixtures

- Clinker burning and Kiln performance including:

- Increase in throughput

- Decrease in energy consumption

- Higher adherence to set-points

- Pryo process improvement including:

- Decrease in energy consumption

- Lower emissions

- Improvements in Cement Preparation processes